Take a moment to consider the satisfying crunch of a puffed cheese curl, the airy crispness of a breakfast cereal, or the uniform shape of a granola bar. These familiar textures are not the result of simple baking or frying; they are the result of a sophisticated and versatile process known as food extrusion. This technology has become the cornerstone of modern snack food production, transforming basic ingredients into a vast array of shapes, sizes, and, most importantly, textures.

The Science of Extrusion: A High-Pressure Transformation

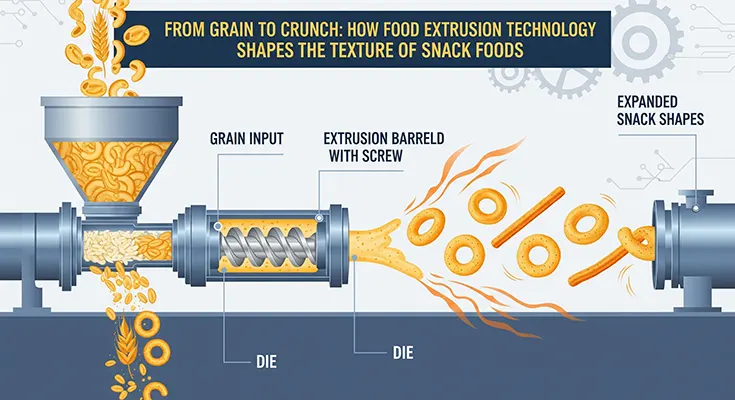

Food extrusion is a process where a mixed ingredient system—typically a dough or paste—is forced through a die, which is a small opening or mold, under a combination of high heat, pressure, and shear. The process takes place within a machine called an extruder, which consists of a long barrel with a rotating screw. As the screw turns, it continuously mixes, heats, and kneads the raw ingredients, creating a semi-molten mass.

The magic happens at the die. As the hot, pressurized mixture exits the die and enters the low-pressure environment of the atmosphere, the superheated water within it instantly flashes into steam. This sudden expansion causes the product to “puff” or “expand,” much like popcorn. This rapid expansion is the key to creating the light, airy, and crispy texture characteristic of many extruded snacks.

The Three Pillars of Texture: Moisture, Heat, and Shear

The final texture of an extruded snack is not an accident; it’s a carefully controlled outcome of manipulating three key variables within the extrusion process:

- Moisture Content: The amount of water in the initial dough mix is a critical factor in determining the final texture. A higher moisture content (above 20%) results in a less expanded, denser product with a smooth surface, like pasta or certain types of breadsticks. Conversely, a lower moisture content (typically 10-15%) leads to greater expansion, creating the characteristic airy and porous structure of puffed snacks.

- Heat (Temperature): The temperature within the extruder’s barrel directly influences the “gelatinization” of starches and the “denaturation” of proteins—two processes essential for texture formation. High temperatures (150-180°C) cause starches to gelatinize and absorb water, forming a cohesive matrix. When this matrix expands at the die, it creates a crisp, fragile texture. Lower temperatures (below 100°C) are used for products that require less expansion, such as dense cereal flakes.

- Shear and Die Design: The mechanical force exerted by the rotating screw on the dough, known as shear, breaks down starch and protein molecules, which affects the final product’s strength and elasticity. The design of the die itself is equally important. The shape and size of the die opening determine the product’s final form (e.g., rings, stars, or tubes). The die can also be designed to create different surface textures, from smooth to rough.

Beyond the Puffs: A World of Textural Variety

While best known for creating puffed snacks, food extrusion is incredibly versatile. By adjusting the process variables, manufacturers can produce a wide range of textures to suit different consumer preferences.

- Dense and Chewy: By using a higher moisture content and lower temperatures, extrusion can produce dense, chewy products like fruit bars, licorice, and certain meat substitutes. In these cases, the focus is on shaping and binding ingredients rather than creating a puffed texture.

- Crispy and Flaky: Products like some breakfast cereals undergo a second process after extrusion, such as flaking and toasting. The extruder forms a dense pellet that is then flattened into flakes and toasted, resulting in a crispy, flaky texture.

- Fibre-Rich and Coarse: Extrusion can incorporate high-fiber ingredients like bran and legumes. The extruder’s kneading action helps bind these components into a uniform product, creating a coarse, fibrous texture that is desired in some health-focused snack bars and cereals.

In essence, food extrusion is a master class in material science applied to food. It’s a technology that allows us to deconstruct raw ingredients and reassemble them into a dazzling array of textures. From the light-as-air puff to the satisfying snap, the texture of our favorite snacks is not a happy accident—it is a testament to the precision and transformative power of food extrusion.